Introduction

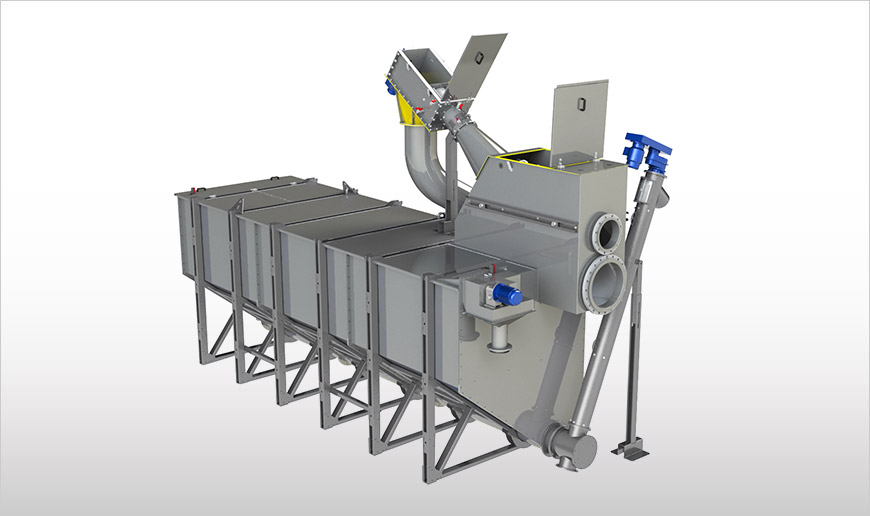

WASTEMASTER TSF2/3 efficiently combines between two and three functions of pre-treatment of sewage from civil or industrial installations.

Easy on-site machine assembly

Optimum footprint-net volume ratio

Technical Specs

Description

The WASTEMASTER TSF2/3 Combined Pre-Treatment Plant consists of a screw screen, a decanting tank, a sand/grit extracting screw and a grease scraper.

Sewage from civil or industrial waste water treatment plants has to be pre-treated before being transferred to any kind of purification system. The WASTEMASTER TSF carries out different processes: de-watering and compacting of screened solid waste, separation of sand/grit and removal of floating, greasy matter.

Function

During the process solids, sand/grit and greasy matter present in the sewage are removed in order to avoid overloading of the downstream treatment system. Waste water enters the plant and is processed by means of separation by screw screen. Subsequently, a sedimentation process and the extraction of the sand or grit takes place. In the TSF3-model an additional degreasing device sees to the removal of fats and suspended solids using an aeration system and a special floating scraper.

Features

- Flow rates of up to 210 litres per second (445 cfm)

- Inlet screen mesh: 0.5 ~ 10 mm

- Sand separation with TSF2/ 3: 90% particle size ≥ 200 μm

- Grease removal with TSF3

- Up to 35% solids volume reduction

- Modular design

Benefits

- No jamming or locking even with fibrous materials due to shaftless spiral

- Volume reduction of solids of up to 35%

- Absence of internal bearings

- Low r.p.m.

- Special long-life screw brushes

- Compact design

- Perfect for over-ground installation especially with limited space available, no civil works required

- Low investment and maintenance costs

- On-site assembly possible

- Heavy-duty screw

- Floating scraper for grease/fat removal

Options

- Alternative voltage and frequency

- Alternative degree of motor protection

- Control panel

- Drive guard

- Screen type

- Overflow

- Chutes

- Fixed internal pipe

- Packaging

Accessories

- Bag clamping system

- Endless tube for screening

- Endless tube for sand